目录

在高纯度产品中使用水解明胶的好处

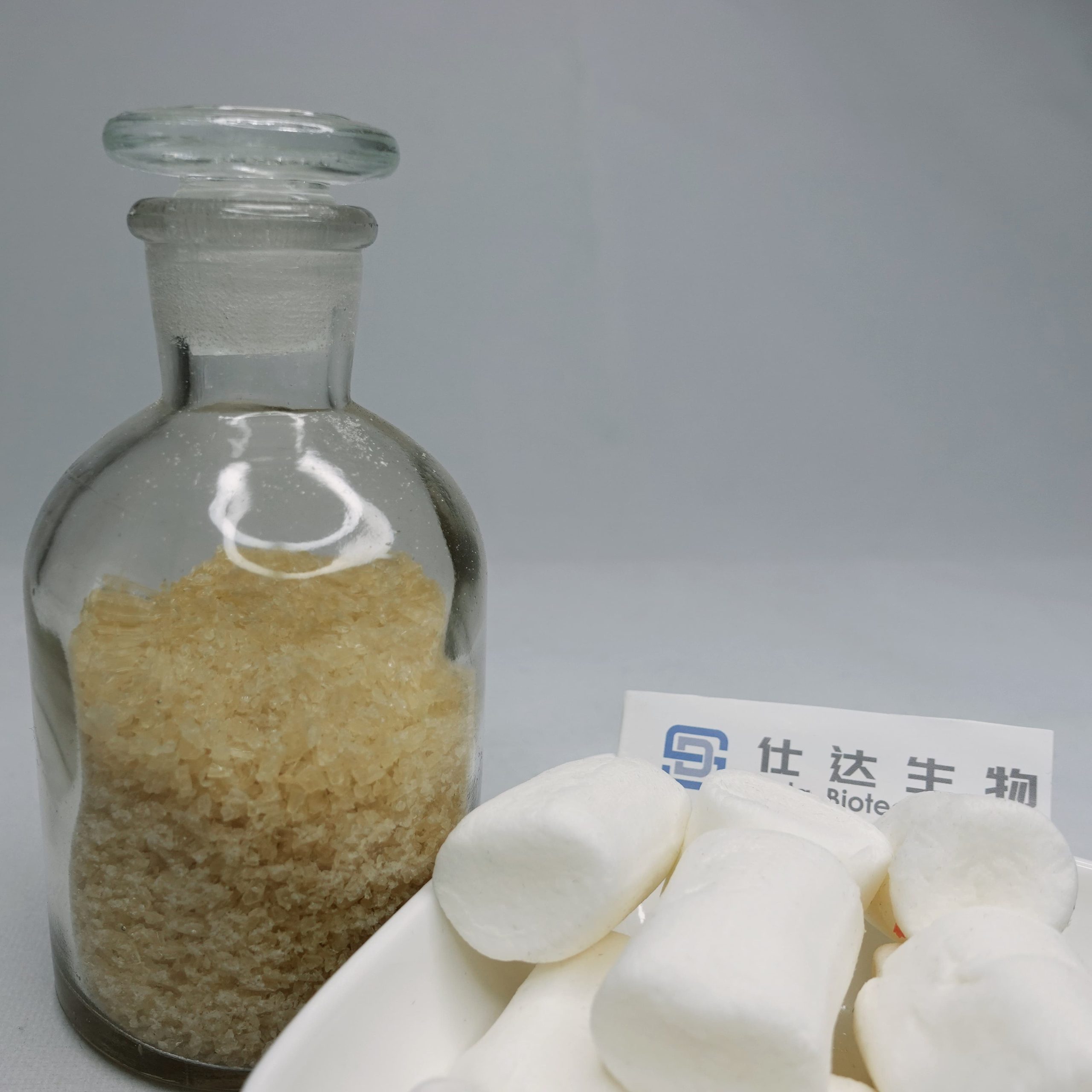

水解明胶是一种多功能成分,广泛用于从食品和饮料到药品和化妆品的产品中。它源自胶原蛋白,胶原蛋白是动物结缔组织中发现的一种蛋白质。水解明胶的过程涉及将蛋白质分解成更小的肽,这使得身体更容易吸收和利用。

在高纯度产品中使用水解明胶的主要好处之一是它能够改善质地和口感食品和饮料。明胶是一种天然胶凝剂,这意味着它可以帮助增稠和稳定汤、酱汁和甜点等产品。当以高纯度形式使用时,水解明胶可以提供干净、透明的外观,没有任何不良的味道或气味。

除了其质地优势外,水解明胶还是蛋白质的来源,这对于维持肌肉质量和健康至关重要。总体健康。它含有身体正常运作所需的所有必需氨基酸,使其成为蛋白质补充剂和代餐产品的宝贵补充。高纯度水解明胶不含污染物和杂质,确保消费者获得安全有效的蛋白质来源。

在高纯度产品中使用水解明胶的另一个优点是它能够支持关节健康。胶原蛋白是软骨的主要成分,软骨是缓冲和保护关节的组织。通过补充水解明胶,个人可以帮助维持关节的完整性并降低患骨关节炎等疾病的风险。明胶的高纯度确保其不含任何可能对关节造成伤害的有害物质。

水解明胶还以其促进皮肤的特性而闻名。胶原蛋白是皮肤中的关键结构蛋白,有助于保持皮肤的弹性和紧致度。通过将水解明胶添加到护肤品中,制造商可以帮助改善皮肤外观并减少衰老迹象。明胶的高纯度确保其在皮肤上使用安全,不会引起任何刺激或不良反应。

总的来说,在高纯度产品中使用水解明胶的好处很多。从其质地特性到蛋白质含量和关节健康益处,水解明胶是一种有价值的成分,可以提高各种产品的质量和有效性。通过选择信誉良好的高纯度水解明胶制造商,消费者可以确信他们正在获得满足其需求的安全可靠的产品。无论是用于食品、饮料、药品还是化妆品,水解明胶都是一种多功能成分,可以为制造商和消费者带来一系列好处。

高纯度水解明胶的制造工艺

水解明胶是一种用途广泛的成分,广泛应用于食品、药品和化妆品等行业。它源自胶原蛋白,胶原蛋白是动物结缔组织中发现的一种蛋白质。制造高纯度水解明胶的过程涉及多个步骤,以确保最终产品符合这些行业要求的严格质量标准。

制造过程的第一步是采购原材料。高纯度水解明胶通常由牛或猪胶原蛋白制成,这些胶原蛋白取自动物的骨骼、皮肤和结缔组织。原材料的质量对最终产品至关重要,因此制造商必须仔细选择符合其纯度和安全规格的供应商。

原材料采购后,将经过一系列加工步骤以提取胶原蛋白并将其转化为明胶。该过程的第一步是水解,涉及通过使用酶或酸将胶原蛋白分子分解成更小的肽。此步骤对于确保明胶具有所需的特性(例如溶解度和胶凝能力)至关重要。

| 理化指标 | ||||

| 项目 | 单位 | 指标要求 | 测试结果 | |

| 感官要求 | / | 淡黄色/黄色 | 浅黄色 | |

| / | 固态 | 固体颗粒 | ||

| / | 无难闻气味 | 无难闻气味 | ||

| Ph | / | 3.5-7.5 | 5.7 | |

| 粘度 | 6.67%60℃ | Map.s | 3.9 | |

| Moisture content | % | ≤14.0 | 9.5 | |

| Ash content | % | ≤2.0 | 1.08 | |

| Condensation strength | Bloom g | ≥50 | 213 | |

| Light transmittanceratio | % | Wavelength450nm≥30Wavelength620nm≥50 | Wavelength450nm:79Wavelength620nm:92 | |

| Water insoluble matter | % | ≤0.2 | 0.01 | |

| Sulfur dioxide | mg/kg | ≤30 | 12 ppm | |

| Superoxide | mg/kg | ≤10 | 0 ppm | |

| Total arsenic (as As). | mg/kg | ≤1.0 | 0.3 | |

| Chromium (as Cr) | mg/kg | ≤2.0 | 0.8 | |

| Lead (as Pb) | mg/kg | ≤1.5 | ≤0.3 | |

After hydrolysis, the gelatin solution is filtered to remove any impurities and then subjected to a series of purification steps to further refine the product. These steps may include processes such as ion exchange chromatography, ultrafiltration, and sterilization to remove any remaining contaminants and ensure the purity of the gelatin.

Once the gelatin has been purified, it is dried into a powder form for ease of handling and storage. The final product is then tested for quality and purity before being packaged and shipped to customers.

Manufacturers of high purity hydrolyzed gelatin must adhere to strict quality control measures throughout the manufacturing process to ensure that the final product meets the specifications of their customers. This includes regular testing of raw materials, in-process samples, and finished products to ensure that they meet the required standards for purity, Safety, and functionality.

In addition to quality control measures, manufacturers of high purity hydrolyzed gelatin must also comply with regulatory requirements set forth by government agencies such as the Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA). These regulations govern the production, labeling, and marketing of gelatin products to ensure that they are safe for consumption and meet the necessary quality standards.

Overall, the process of manufacturing high purity hydrolyzed gelatin is a complex and highly regulated process that requires careful attention to detail and adherence to strict quality control measures. By following these guidelines, manufacturers can produce a product that meets the stringent requirements of the food, pharmaceutical, and cosmetic industries and provides customers with a high-quality ingredient for their products.

Applications of Hydrolyzed Gelatin in Various Industries

Hydrolyzed gelatin, also known as Collagen hydrolysate, is a versatile ingredient that finds applications in various industries due to its unique properties. As a manufacturer of high-purity hydrolyzed gelatin, we understand the importance of quality and consistency in meeting the needs of our customers across different sectors.

In the food industry, hydrolyzed gelatin is widely used as a gelling agent, stabilizer, and thickener in a variety of products. Its ability to form a gel-like structure makes it an essential ingredient in Confectionery, dairy, and meat products. Additionally, hydrolyzed gelatin is often used in the production of dietary supplements and functional foods due to its high Protein content and collagen-boosting properties.

In the pharmaceutical industry, hydrolyzed gelatin plays a crucial role in the formulation of capsules, tablets, and coatings. Its compatibility with a wide range of active ingredients and its ability to improve the bioavailability of drugs make it a preferred choice for pharmaceutical manufacturers. Furthermore, hydrolyzed gelatin is used in wound dressings and medical devices due to its biocompatibility and wound-healing properties.

In the cosmetic industry, hydrolyzed gelatin is valued for its skin-rejuvenating and anti-aging properties. It is commonly used in skincare products such as creams, lotions, and masks to improve skin elasticity, hydration, and firmness. Additionally, hydrolyzed gelatin is used in hair care products to strengthen hair follicles and promote hair growth.

In the nutraceutical industry, hydrolyzed gelatin is a popular ingredient in collagen supplements and joint health products. Its high protein content and Amino Acid profile make it an ideal choice for promoting bone, joint, and muscle health. Furthermore, hydrolyzed gelatin is used in Sports Nutrition products to support muscle recovery and enhance athletic performance.

In the textile industry, hydrolyzed gelatin is utilized in the production of specialty fibers and fabrics. Its film-forming properties and moisture-retention capabilities make it an excellent sizing agent for yarns and textiles. Additionally, hydrolyzed gelatin is used in the printing and dyeing of fabrics to improve color fastness and durability.

In the photography industry, hydrolyzed gelatin is a key component in the production of photographic emulsions and coatings. Its ability to form a stable gel and absorb light makes it an essential ingredient in the development of high-quality photographic materials. Furthermore, hydrolyzed gelatin is used in the restoration and preservation of historical photographs and documents.

In conclusion, the applications of hydrolyzed gelatin in various industries are vast and diverse. As a manufacturer of high-purity hydrolyzed gelatin, we are committed to providing our customers with top-quality products that meet their specific needs and requirements. Whether it’s in food, pharmaceutical, cosmetic, nutraceutical, textile, or photography applications, hydrolyzed gelatin continues to be a valuable ingredient that enhances the quality and performance of products across different sectors.