Table of Contents

Benefits of Using Hydrolyzed Gelatin in High Purity Products

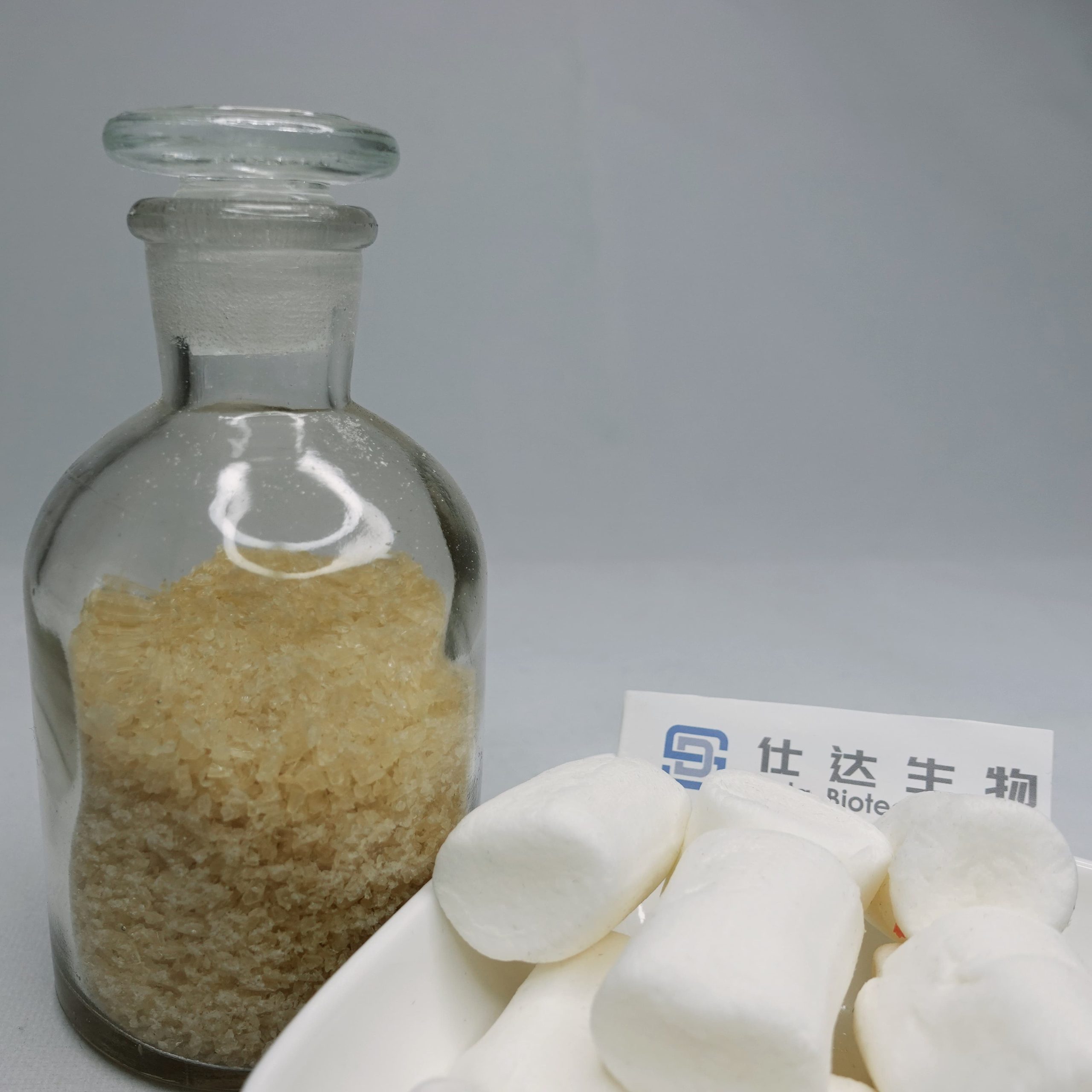

Hydrolyzed gelatin is a versatile ingredient that is used in a wide range of products, from food and Beverages to pharmaceuticals and cosmetics. It is derived from Collagen, which is a Protein found in the connective tissues of animals. The process of hydrolyzing gelatin involves breaking Down the protein into smaller peptides, which makes it easier for the body to absorb and utilize. One of the key benefits of using hydrolyzed gelatin in high purity products is its ability to improve the texture and mouthfeel of food and beverages. Gelatin is a natural gelling agent, which means it can help to thicken and stabilize products such as soups, sauces, and Desserts. When used in high purity form, hydrolyzed gelatin can provide a clean and clear appearance, without any unwanted taste or odor. In addition to its textural benefits, hydrolyzed gelatin is also a source of protein, which is essential for maintaining muscle mass and overall health. It contains all of the essential amino acids that the body needs to function properly, making it a valuable addition to protein supplements and meal replacement products. High purity hydrolyzed gelatin is free from contaminants and impurities, ensuring that consumers are getting a safe and effective source of protein. Another advantage of using hydrolyzed gelatin in high purity products is its ability to support joint health. Collagen is a major component of cartilage, which is the tissue that cushions and protects the joints. By supplementing with hydrolyzed gelatin, individuals can help to maintain the integrity of their joints and reduce the risk of conditions such as osteoarthritis. The high purity of the gelatin ensures that it is free from any harmful substances that could potentially cause harm to the joints. Hydrolyzed gelatin is also known for its skin-boosting properties. Collagen is a key structural protein in the skin, helping to maintain its elasticity and firmness. By incorporating hydrolyzed gelatin into skincare products, manufacturers can help to improve the appearance of the skin and reduce the signs of aging. The high purity of the gelatin ensures that it is safe for use on the skin, without causing any irritation or adverse reactions. Overall, the benefits of using hydrolyzed gelatin in high purity products are numerous. From its textural properties to its protein content and joint health benefits, hydrolyzed gelatin is a valuable ingredient that can enhance the quality and effectiveness of a wide range of products. By choosing a reputable manufacturer of high purity hydrolyzed gelatin, consumers can be confident that they are getting a safe and reliable product that meets their needs. Whether used in food, beverages, pharmaceuticals, or cosmetics, hydrolyzed gelatin is a versatile ingredient that can provide a range of benefits for both manufacturers and consumers alike.The Process of Manufacturing High Purity Hydrolyzed Gelatin

Hydrolyzed gelatin is a versatile ingredient that is used in a wide range of industries, including food, pharmaceuticals, and cosmetics. It is derived from collagen, which is a protein found in the connective tissues of animals. The process of manufacturing high purity hydrolyzed gelatin involves several steps to ensure that the final product meets the strict quality standards required by these industries. The first step in the manufacturing process is sourcing the raw materials. High purity hydrolyzed gelatin is typically made from bovine or porcine collagen, which is obtained from the bones, skin, and connective tissues of animals. The quality of the raw materials is crucial to the final product, so manufacturers must carefully select suppliers that meet their specifications for purity and Safety. Once the raw materials have been sourced, they are subjected to a series of processing steps to extract the collagen and convert it into gelatin. The first step in this process is hydrolysis, which involves breaking down the collagen molecules into smaller peptides through the use of Enzymes or acids. This step is crucial for ensuring that the gelatin has the desired properties, such as solubility and gelling ability.

Once the raw materials have been sourced, they are subjected to a series of processing steps to extract the collagen and convert it into gelatin. The first step in this process is hydrolysis, which involves breaking down the collagen molecules into smaller peptides through the use of Enzymes or acids. This step is crucial for ensuring that the gelatin has the desired properties, such as solubility and gelling ability.

| Physical and chemical Indicators | ||||

| Item | Unit | Indicator requirements | Test results | |

| Sensory requirements | / | Light yellow /yellow | Light yellow | |

| / | Solid state | Solid particles | ||

| / | No unpleasant odor | No unpleasant odor | ||

| Ph | / | 3.5-7.5 | 5.7 | |

| Viscosity | 6.67%60\u2103 | Map.s | 3.9 | |

| Moisture content | % | \u226414.0 | 9.5 | |

| Ash content | % | \u22642.0 | 1.08 | |

| Condensation strength | Bloom g | \u226550 | 213 | |

| Light transmittanceratio | % | Wavelength450nm\u226530Wavelength620nm\u226550 | Wavelength450nm:79Wavelength620nm:92 | |

| Water insoluble matter | % | \u22640.2 | 0.01 | |

| Sulfur dioxide | mg/kg | \u226430 | 12 ppm | |

| Superoxide | mg/kg | \u226410 | 0 ppm | |

| Total arsenic (as As). | mg/kg | \u22641.0 | 0.3 | |

| Chromium (as Cr) | mg/kg | \u22642.0 | 0.8 | |

| Lead (as Pb) | mg/kg | \u22641.5 | \u22640.3 | |

Applications of Hydrolyzed Gelatin in Various Industries

Hydrolyzed gelatin, also known as collagen hydrolysate, is a versatile ingredient that finds applications in various industries due to its unique properties. As a manufacturer of high-purity hydrolyzed gelatin, we understand the importance of quality and consistency in meeting the needs of our customers across different sectors. In the food industry, hydrolyzed gelatin is widely used as a gelling agent, stabilizer, and thickener in a variety of products. Its ability to form a gel-like structure makes it an essential ingredient in Confectionery, dairy, and meat products. Additionally, hydrolyzed gelatin is often used in the production of dietary supplements and functional foods due to its high protein content and collagen-boosting properties. In the pharmaceutical industry, hydrolyzed gelatin plays a crucial role in the formulation of capsules, tablets, and coatings. Its compatibility with a wide range of active ingredients and its ability to improve the bioavailability of drugs make it a preferred choice for pharmaceutical manufacturers. Furthermore, hydrolyzed gelatin is used in wound dressings and medical devices due to its biocompatibility and wound-healing properties. In the cosmetic industry, hydrolyzed gelatin is valued for its skin-rejuvenating and anti-aging properties. It is commonly used in skincare products such as creams, lotions, and masks to improve skin elasticity, hydration, and firmness. Additionally, hydrolyzed gelatin is used in hair care products to strengthen hair follicles and promote hair growth. In the nutraceutical industry, hydrolyzed gelatin is a popular ingredient in collagen supplements and joint health products. Its high protein content and Amino Acid profile make it an ideal choice for promoting bone, joint, and muscle health. Furthermore, hydrolyzed gelatin is used in Sports Nutrition products to support muscle recovery and enhance athletic performance. In the textile industry, hydrolyzed gelatin is utilized in the production of specialty fibers and fabrics. Its film-forming properties and moisture-retention capabilities make it an excellent sizing agent for yarns and textiles. Additionally, hydrolyzed gelatin is used in the printing and dyeing of fabrics to improve color fastness and durability.

In the photography industry, hydrolyzed gelatin is a key component in the production of photographic emulsions and coatings. Its ability to form a stable gel and absorb light makes it an essential ingredient in the development of high-quality photographic materials. Furthermore, hydrolyzed gelatin is used in the restoration and preservation of historical photographs and documents.

In conclusion, the applications of hydrolyzed gelatin in various industries are vast and diverse. As a manufacturer of high-purity hydrolyzed gelatin, we are committed to providing our customers with top-quality products that meet their specific needs and requirements. Whether it’s in food, pharmaceutical, cosmetic, nutraceutical, textile, or photography applications, hydrolyzed gelatin continues to be a valuable ingredient that enhances the quality and performance of products across different sectors.

In the textile industry, hydrolyzed gelatin is utilized in the production of specialty fibers and fabrics. Its film-forming properties and moisture-retention capabilities make it an excellent sizing agent for yarns and textiles. Additionally, hydrolyzed gelatin is used in the printing and dyeing of fabrics to improve color fastness and durability.

In the photography industry, hydrolyzed gelatin is a key component in the production of photographic emulsions and coatings. Its ability to form a stable gel and absorb light makes it an essential ingredient in the development of high-quality photographic materials. Furthermore, hydrolyzed gelatin is used in the restoration and preservation of historical photographs and documents.

In conclusion, the applications of hydrolyzed gelatin in various industries are vast and diverse. As a manufacturer of high-purity hydrolyzed gelatin, we are committed to providing our customers with top-quality products that meet their specific needs and requirements. Whether it’s in food, pharmaceutical, cosmetic, nutraceutical, textile, or photography applications, hydrolyzed gelatin continues to be a valuable ingredient that enhances the quality and performance of products across different sectors.