Table of Contents

How to Maximize Efficiency with Universal External Cylindrical Grinder Machine

Universal external cylindrical grinder machines are essential tools in the manufacturing industry for precision grinding of cylindrical components. These machines are versatile and can be used for a wide range of applications, including grinding internal and external surfaces, as well as holes and threads. One of the best-selling models in this category is the M1432 MW1432B, known for its high efficiency and accuracy in grinding operations.

To maximize efficiency with a universal external cylindrical grinder machine, it is important to understand the key features and capabilities of the machine. The M1432 MW1432B grinder is equipped with a powerful spindle motor that allows for high-speed grinding operations. This machine also has a large grinding depth of up to 125mm, making it suitable for grinding both small and large components.

When using a universal external cylindrical grinder machine, it is important to properly set up the workpiece and adjust the machine settings to achieve the desired grinding results. The M1432 MW1432B grinder comes with a range of Accessories and attachments that can be used to grind internal and external surfaces, as well as holes and threads. By using the appropriate attachments and adjusting the machine settings, you can maximize the efficiency of the grinding process and achieve precise results.

In addition to proper setup and adjustment, it is also important to use the right grinding wheel for the job. The M1432 MW1432B grinder is compatible with a variety of Grinding Wheels, including diamond and CBN wheels, which are ideal for grinding hard materials such as steel and carbide. By selecting the right grinding wheel for the material being worked on, you can achieve faster grinding speeds and better surface finishes.

Another key factor in maximizing efficiency with a universal external cylindrical grinder machine is to maintain the machine properly. Regular maintenance and cleaning of the machine can help prevent wear and tear on the components, ensuring that the machine operates smoothly and efficiently. It is also important to regularly inspect the machine for any signs of damage or wear, and to replace any worn or damaged parts as needed.

In conclusion, the M1432 MW1432B universal external cylindrical grinder machine is a versatile and efficient tool for precision grinding operations. By understanding the key features and capabilities of the machine, properly setting up the workpiece, using the right grinding wheel, and maintaining the machine properly, you can maximize efficiency and achieve precise grinding results. Whether you are grinding internal and external surfaces, holes, or threads, the M1432 MW1432B grinder is a reliable and high-performance machine that can help you meet your manufacturing needs.

The Benefits of Using Internal Grinding on M1432 MW1432B Machine

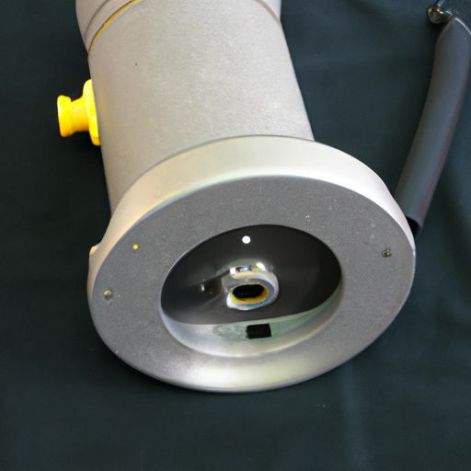

Internal grinding is a crucial process in the manufacturing industry, as it allows for the precise finishing of inner surfaces of workpieces. One of the most popular machines used for internal grinding is the M1432 MW1432B universal external cylindrical grinder machine. This machine is known for its versatility and efficiency in grinding both inner and outer holes with a maximum grinding depth of 125mm.

One of the key benefits of using the M1432 MW1432B machine for internal grinding is its ability to achieve high Levels of precision. The machine is equipped with advanced technology that allows for accurate and consistent grinding of inner surfaces, ensuring that the final product meets the required specifications. This level of precision is essential in industries such as aerospace, automotive, and medical, where even the smallest deviation can Lead to significant issues.

In addition to precision, the M1432 MW1432B machine also offers a high level of efficiency. The machine is designed to operate at high speeds, allowing for quick and efficient grinding of workpieces. This not only helps to increase productivity but also reduces the overall production time, leading to cost savings for manufacturers. Furthermore, the machine is equipped with a powerful motor that can handle a wide range of materials, making it suitable for a variety of applications.

Another benefit of using the M1432 MW1432B machine for internal grinding is its versatility. The machine is capable of grinding both inner and outer holes, making it ideal for a wide range of applications. Whether you need to grind a small hole or a larger one, the machine can handle it with ease. This versatility makes the M1432 MW1432B machine a valuable asset for manufacturers who work with a variety of workpieces.

Furthermore, the M1432 MW1432B machine is known for its durability and reliability. The machine is built to withstand the rigors of daily use in a manufacturing Environment, ensuring that it will continue to perform at a high level for years to come. This reliability is essential for manufacturers who rely on their equipment to consistently produce high-quality products.

Overall, the M1432 MW1432B universal external cylindrical grinder machine is a top-selling machine for internal grinding due to its precision, efficiency, versatility, durability, and reliability. Whether you are working in the aerospace, automotive, or medical industry, this machine is sure to meet your internal grinding needs. With its advanced technology and high-performance capabilities, the M1432 MW1432B machine is a valuable asset for any manufacturer looking to achieve superior results in their internal grinding processes.