Table of Contents

Benefits of Using Tungsten Steel Carbide Blade for Sheet Cutting

Sheet cutting is a common task in various industries, from manufacturing to construction. The quality of the cutting blade used can significantly impact the efficiency and precision of the cutting process. One type of blade that has gained popularity for its durability and sharpness is the tungsten steel carbide blade.

Tungsten steel carbide Blades are known for their exceptional hardness and resistance to wear. This makes them ideal for cutting tough materials like metal sheets, plastics, and composites. The hardness of tungsten steel carbide allows the blade to maintain its sharpness for a longer period, reducing the need for frequent blade changes and increasing productivity.

One of the key benefits of using a tungsten steel carbide blade for sheet cutting is its durability. Unlike traditional steel blades that can dull quickly when cutting hard materials, tungsten steel carbide blades can withstand the rigors of cutting tough materials without losing their sharpness. This durability not only extends the lifespan of the blade but also ensures consistent cutting performance over time.

In addition to durability, tungsten steel carbide blades are also known for their precision. The hardness of the blade allows for clean and precise cuts, even when working with thick or dense materials. This precision is essential in industries where accuracy is paramount, such as in the manufacturing of electronic components or precision parts.

Another advantage of using tungsten steel carbide blades for sheet cutting is their versatility. These blades can be used to cut a wide range of materials, from soft plastics to hard metals, making them a versatile tool for various cutting applications. Whether you are cutting thin sheets of Aluminum or thick sheets of Stainless Steel, a tungsten steel carbide blade can provide the sharpness and durability needed to get the job done.

When it comes to quality, tungsten steel carbide blades are at the top of the list. These blades are manufactured to strict standards to ensure consistent performance and reliability. The high-quality materials used in the production of tungsten steel carbide blades make them a reliable choice for professionals who demand the best in their cutting tools.

One common type of tungsten steel carbide blade used for sheet cutting is the standard three-hole blade. This blade is designed for use in rotary cutters and provides a smooth and precise cutting action. The three-hole design allows for easy installation and replacement, making it a convenient option for busy work environments.

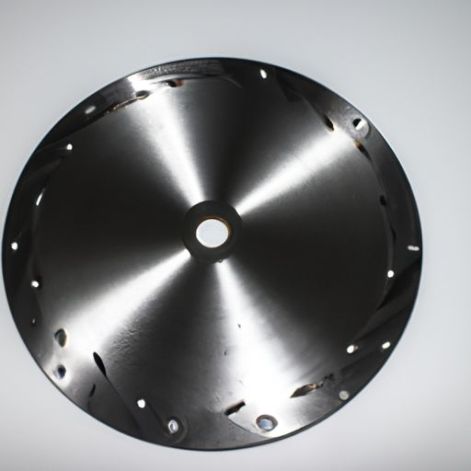

For those looking for a more specialized cutting tool, there are also top-quality circular tungsten steel carbide blades available. These blades are designed for cutting circular shapes in materials like metal sheets and plastics. The circular design allows for precise and efficient cutting, making them ideal for applications where accuracy is crucial.

In conclusion, the benefits of using tungsten steel carbide blades for sheet cutting are clear. From their durability and precision to their versatility and quality, these blades offer a superior cutting experience for professionals in various industries. Whether you are cutting thin sheets of plastic or thick sheets of metal, a tungsten steel carbide blade can provide the sharpness and reliability needed to get the job done right.