Table of Contents

The Process of Recycling Plastic Flakes into Pellets

Plastic pollution is a pressing issue that continues to plague our Environment. With millions of tons of plastic waste being generated each year, finding sustainable solutions for recycling and reusing plastic materials is crucial. One such solution is the process of recycling plastic flakes into pellets, which can then be used to create new products.

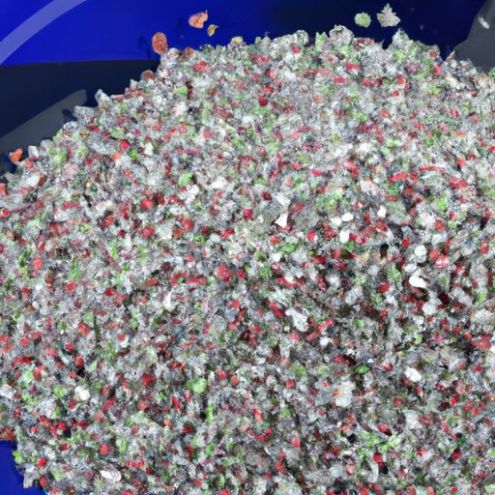

The first step in this process is collecting plastic waste and sorting it by type. This is important because different types of plastic have different properties and melting points, so they need to be separated before they can be processed. Once the plastic flakes have been sorted, they are washed and cleaned to remove any contaminants or impurities.

After the plastic flakes have been cleaned, they are melted Down and extruded into pellets. This is done using a machine called a granulator, which heats the plastic to a specific temperature and then forces it through a die to create small pellets. These pellets can then be used as raw material for manufacturing new Plastic Products.

One innovative method for creating plastic pellets is underwater cutting. In this process, the molten plastic is extruded into a water bath, where it solidifies and is then cut into pellets using a rotating blade. This method is particularly effective for processing materials like LDPE and PET, which can be difficult to cut using traditional methods.

The use of underwater cutting technology has revolutionized the recycling industry, making it easier and more efficient to create high-quality plastic pellets from recycled materials. By using this method, manufacturers can produce pellets that are uniform in size and shape, making them ideal for use in injection molding and extrusion processes.

In addition to creating new products from Recycled Plastic pellets, this process also helps to reduce the amount of plastic waste that ends up in landfills or oceans. By recycling plastic flakes into pellets, we can give new life to materials that would otherwise be discarded, helping to conserve natural resources and reduce our carbon footprint.

Overall, the process of recycling plastic flakes into pellets is a sustainable and environmentally friendly solution for managing plastic waste. By using innovative technologies like underwater cutting and granulation, we can create high-quality pellets that can be used to manufacture a wide range of products. This not only helps to reduce the amount of plastic waste in our environment but also promotes a circular economy where materials are reused and recycled to create a more sustainable future.