Table of Contents

The Dangers of Mold Growth on Plastic PET Preforms

Plastic PET preforms are a popular choice for packaging various products, thanks to their durability, lightweight, and versatility. However, one of the biggest challenges faced by manufacturers and consumers alike is the growth of mold on these preforms. Mold growth on plastic PET preforms can pose serious health risks and compromise the quality of the products they contain.

Mold thrives in warm, damp environments, making plastic PET preforms an ideal breeding ground. When mold spores Land on the surface of a preform, they can quickly multiply and spread, forming a visible layer of mold. This not only affects the appearance of the preform but also poses a health hazard to consumers who come into contact with the contaminated product.

The presence of mold on plastic PET preforms can also compromise the integrity of the packaging. Mold can weaken the structure of the preform, making it more susceptible to damage during transportation and storage. This can result in leaks and spoilage of the product, leading to financial losses for manufacturers and dissatisfaction among consumers.

To prevent mold growth on plastic PET preforms, it is essential to take proactive measures to maintain a clean and dry Environment. Proper storage conditions, such as keeping preforms in a cool, dry place away from direct sunlight, can help prevent mold growth. Regular cleaning and inspection of preforms can also help identify and address any mold growth before it becomes a serious issue.

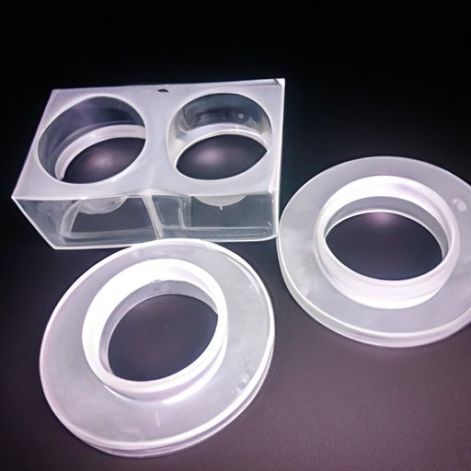

In addition to proper storage and maintenance, choosing the right material for plastic PET preforms can also help prevent mold growth. Hot sale product plastic material pet size 28mm 30mm PET preforms are specifically designed to resist mold growth, thanks to their high-quality construction and durability. These preforms are made from a special type of plastic that is resistant to mold and other contaminants, ensuring the Safety and quality of the products they contain.

Despite the best efforts to prevent mold growth, it is important for manufacturers and consumers to be vigilant and proactive in addressing any signs of mold on plastic PET preforms. If mold is detected on a preform, it is crucial to take immediate action to clean and disinfect the affected area. This may involve using a mild detergent or Bleach solution to remove the mold and prevent it from spreading further.

In conclusion, mold growth on plastic PET preforms is a serious issue that can have far-reaching consequences for manufacturers and consumers alike. By taking proactive measures to prevent mold growth, such as proper storage, regular cleaning, and choosing the right material, the risks associated with mold contamination can be minimized. It is essential for all stakeholders in the supply chain to work together to ensure the safety and quality of products packaged in plastic PET preforms.

How to Prevent and Remove Mold from Hot Sale Plastic PET Preforms

Mold can be a common issue when it comes to plastic PET preforms, especially in hot sale products. Mold not only affects the appearance of the preforms but can also impact their quality and safety. It is important to take preventive measures to avoid mold growth and to know how to properly remove it if it does occur.

One of the best ways to prevent mold from forming on plastic PET preforms is to store them in a cool, dry place. Mold thrives in warm, damp environments, so keeping the preforms in a cool area with good air circulation can help prevent mold growth. Additionally, make sure to inspect the preforms regularly for any signs of mold and address the issue promptly.

Another preventive measure is to properly clean and sanitize the preforms before use. This can help remove any existing mold spores and prevent new ones from forming. Use a mild detergent and warm water to clean the preforms, and make sure to dry them thoroughly before use. Additionally, consider using a mold inhibitor or anti-fungal spray to further prevent mold growth.

If mold does form on the plastic PET preforms, it is important to take immediate action to remove it. Mold can be harmful if ingested, so it is crucial to properly clean and sanitize the preforms before using them. To remove mold from the preforms, start by scrubbing them with a mixture of water and Vinegar or bleach. Make sure to wear gloves and a mask to protect yourself from the mold spores.

After scrubbing the preforms, rinse them thoroughly with clean water and dry them completely before use. It is also a good idea to inspect the preforms for any signs of mold regrowth and address the issue promptly. If the mold persists, consider using a stronger mold remover or seeking professional help.

After scrubbing the preforms, rinse them thoroughly with clean water and dry them completely before use. It is also a good idea to inspect the preforms for any signs of mold regrowth and address the issue promptly. If the mold persists, consider using a stronger mold remover or seeking professional help.

In addition to cleaning and sanitizing the preforms, it is important to address the root cause of the mold growth. This may involve improving ventilation in the storage area, reducing humidity Levels, or addressing any other factors that may be contributing to mold growth. By taking proactive measures to prevent mold growth and properly removing any existing mold, you can ensure the quality and safety of your hot sale plastic PET preforms.

In conclusion, mold can be a common issue when it comes to plastic PET preforms, especially in hot sale products. It is important to take preventive measures to avoid mold growth and to know how to properly remove it if it does occur. By storing the preforms in a cool, dry place, cleaning and sanitizing them regularly, and addressing any mold growth promptly, you can ensure the quality and safety of your products. Remember to always wear Protective Gear when dealing with mold and seek professional help if needed.