Table of Contents

Overview of Casing Pipe

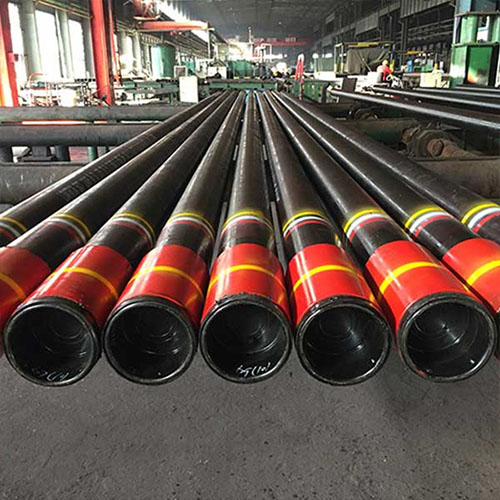

Casing pipe is a crucial component in the construction of oil and gas wells. It is a large-diameter pipe that is inserted into a drilled borehole to provide structural integrity and support for the wellbore. Casing pipe is typically made of steel and comes in various sizes and grades to suit different drilling conditions and requirements.

One of the primary functions of casing pipe is to prevent the collapse of the wellbore walls. When a well is drilled, the surrounding rock formations can exert pressure on the borehole, causing it to collapse. Casing pipe acts as a barrier between the wellbore and the surrounding formations, ensuring that the well remains stable and secure.

In addition to providing structural support, casing pipe also helps to isolate different zones within the well. In oil and gas wells, it is common to encounter multiple layers of rock formations with varying properties. By installing casing pipe, operators can isolate and protect these different zones, preventing the mixing of fluids and ensuring the efficient production of oil and gas.

Casing pipe also plays a crucial role in preventing the contamination of groundwater. In many drilling operations, the wellbore passes through aquifers and other water-bearing formations. Without proper casing, there is a risk of fluids from the wellbore leaking into these formations and contaminating the groundwater. Casing pipe acts as a barrier, preventing the migration of fluids and protecting the Environment.

There are several types of casing pipe available, each designed for specific applications and drilling conditions. The most common types of casing pipe include conductor casing, surface casing, intermediate casing, and production casing. Conductor casing is the first casing string installed in a well and is used to stabilize the upper part of the wellbore. Surface casing is installed to protect groundwater and isolate shallow formations. Intermediate casing is used to isolate specific zones within the well, while production casing is the final casing string that allows for the production of oil and gas.

Casing pipe is subject to stringent quality control measures to ensure its integrity and reliability. Before being installed in a well, casing pipe undergoes rigorous testing to verify its mechanical properties, chemical composition, and dimensional accuracy. This ensures that the casing pipe can withstand the extreme conditions encountered in drilling operations and provides long-lasting protection for the wellbore.

In conclusion, casing pipe is a critical component in the construction of oil and gas wells. It provides structural support, isolates different zones within the well, and protects groundwater from contamination. With various types and grades available, casing pipe can be tailored to suit different drilling conditions and requirements. By ensuring the quality and integrity of casing pipe, operators can build safe and efficient wells that maximize the production of oil and gas.