Table of Contents

Benefits of Using Factory Direct Customized Size Hot DIP Round Galvanized Steel Tube

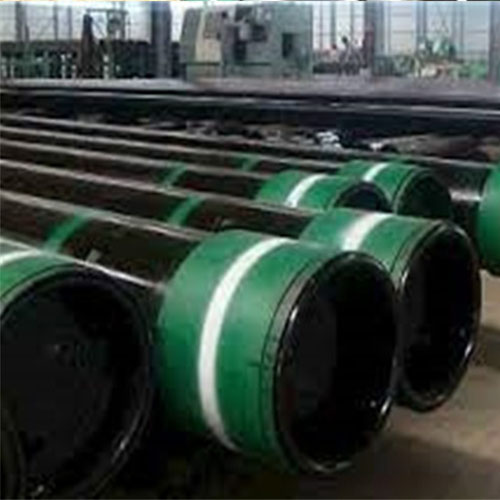

When it comes to constructing pipelines for oil and gas transportation, the choice of materials is crucial. One of the most popular options in the industry is hot-dip galvanized steel tubes, specifically ASTM A53 black pipes. These pipes are known for their durability, strength, and resistance to corrosion, making them ideal for use in demanding environments.

One of the key advantages of using factory direct customized size hot-dip round galvanized steel tubes is their superior strength. These pipes are made from high-quality steel that has been hot-dip galvanized to provide an extra layer of protection against corrosion. This makes them ideal for use in pipelines that are exposed to harsh environmental conditions, such as those found in the oil and gas industry.

In addition to their strength, hot-dip galvanized steel tubes are also highly durable. The galvanization process creates a protective barrier that helps to prevent rust and corrosion, extending the lifespan of the pipes and reducing the need for costly repairs or replacements. This makes them a cost-effective choice for companies looking to build long-lasting pipelines that can withstand the test of time.

Another benefit of using factory direct customized size hot-dip round galvanized steel tubes is their versatility. These pipes can be customized to meet the specific size and shape requirements of any project, making them suitable for a wide range of applications. Whether you need a small diameter pipe for a residential gas line or a large diameter pipe for a major oil pipeline, hot-dip galvanized steel tubes can be tailored to fit your needs.

Furthermore, hot-dip galvanized steel tubes are easy to install and maintain. Their smooth surface and uniform thickness make them simple to work with, reducing the time and labor required for installation. Once in place, these pipes require minimal maintenance, saving companies time and money in the long run.

In addition to their practical benefits, factory direct customized size hot-dip round galvanized steel tubes are also environmentally friendly. The galvanization process used to coat the pipes is non-toxic and produces minimal waste, making it a sustainable choice for companies looking to reduce their environmental impact. By choosing hot-dip galvanized steel tubes, companies can build pipelines that are not only strong and durable but also eco-friendly.

Overall, the benefits of using factory direct customized size hot-dip round galvanized steel tubes for oil and gas pipelines are clear. From their superior strength and durability to their versatility and ease of installation, these pipes offer a range of advantages that make them an excellent choice for companies in the industry. By investing in high-quality hot-dip galvanized steel tubes, companies can build pipelines that are built to last, ensuring the safe and efficient transportation of oil and gas for years to come.

Importance of ASTM A53 Black Pipe Carbon Seamless Steel Pipe in Oil and Gas Pipeline Industry

The oil and gas industry plays a crucial role in powering our modern world. From fueling vehicles to heating homes, oil and gas are essential resources that keep our society running smoothly. In order to transport these valuable resources from extraction sites to end users, a reliable and efficient pipeline system is necessary. This is where ASTM A53 black pipe carbon seamless steel pipe comes into play.

ASTM A53 black pipe carbon seamless steel pipe is a high-quality, durable material that is commonly used in the construction of oil and gas pipelines. Its seamless design ensures a smooth flow of oil and gas, reducing the risk of leaks and ensuring the safe and efficient transportation of these valuable resources. Additionally, its black coating provides protection against corrosion, extending the lifespan of the pipeline and reducing maintenance costs.

One of the key advantages of ASTM A53 black pipe carbon seamless steel pipe is its ability to be customized to fit the specific needs of a project. With factory direct customization options available, companies can order pipes in a variety of sizes to meet the requirements of their pipeline system. This flexibility allows for greater efficiency in pipeline construction, as pipes can be tailored to fit the unique specifications of each project.

In addition to its customizable size options, ASTM A53 black pipe carbon seamless steel pipe is also known for its high strength and durability. This makes it an ideal choice for oil and gas pipelines, which are often subjected to harsh environmental conditions and high pressure. The strength of ASTM A53 black pipe carbon seamless steel pipe ensures that it can withstand the rigors of pipeline transportation, providing a reliable and long-lasting solution for the oil and gas industry.

Furthermore, ASTM A53 black pipe carbon seamless steel pipe is manufactured to meet strict industry standards, ensuring that it meets the necessary requirements for use in oil and gas pipelines. This includes compliance with ASTM A53 specifications, which outline the minimum requirements for seamless Carbon Steel pipe. By using ASTM A53 black pipe carbon seamless steel pipe, companies can be confident that they are using a high-quality product that meets industry standards for Safety and performance.

Overall, ASTM A53 black pipe carbon seamless steel pipe plays a vital role in the oil and gas industry by providing a reliable and efficient solution for pipeline construction. Its customizable size options, high strength, and durability make it an ideal choice for Transporting oil and gas from extraction sites to end users. By using ASTM A53 black pipe carbon seamless steel pipe, companies can ensure the safe and efficient transportation of these valuable resources, helping to power our modern world.