Table of Contents

Advantages of Using Extruded Aluminum Tube Machine for Coated Aluminum Coil

Extruded aluminum tube machines are a popular choice for coating aluminum coils to create round tubes. These machines offer a number of advantages that make them a preferred option for manufacturers looking to produce high-quality coated aluminum tubes efficiently and effectively.

One of the key advantages of using an extruded aluminum tube machine for coated aluminum coil production is the precision and consistency it offers. These machines are designed to extrude aluminum coils with a high level of accuracy, ensuring that the resulting round tubes are uniform in size and shape. This precision is essential for ensuring that the tubes meet the required specifications and standards for the intended application.

In addition to precision, extruded aluminum tube machines are also highly efficient. These machines are capable of producing large quantities of coated aluminum tubes in a relatively short amount of time, making them ideal for high-volume production runs. This efficiency can help manufacturers reduce production costs and increase overall productivity, making extruded aluminum tube machines a cost-effective solution for coated aluminum coil production.

Another advantage of using an extruded aluminum tube machine for coated aluminum coil production is the versatility it offers. These machines can be used to produce round tubes in a wide range of sizes and thicknesses, making them suitable for a variety of applications. Whether you need small, lightweight tubes for a consumer product or large, heavy-duty tubes for industrial use, an extruded aluminum tube machine can be customized to meet your specific requirements.

Furthermore, extruded aluminum tube machines are capable of applying a variety of coatings to the aluminum coils, including powder coatings, anodized finishes, and painted finishes. This versatility allows manufacturers to create coated aluminum tubes with different colors, textures, and properties, making them suitable for a wide range of applications. Whether you need tubes that are corrosion-resistant, heat-resistant, or simply aesthetically pleasing, an extruded aluminum tube machine can help you achieve the desired results.

In conclusion, extruded aluminum tube machines offer a number of advantages for coated aluminum coil production. From precision and efficiency to versatility and customization options, these machines are a reliable and cost-effective solution for manufacturers looking to produce high-quality coated aluminum tubes. Whether you are producing tubes for consumer products, industrial applications, or any other purpose, an extruded aluminum tube machine can help you meet your production goals and deliver superior results.

Step-by-Step Guide on Coating Round Tubes with Extruded Aluminum Tube Machine

Extruded aluminum tube machine coated aluminum coil for round tubes is a process that involves applying a protective coating to aluminum coils before they are formed into round tubes. This coating helps to protect the aluminum from corrosion and other environmental factors, ensuring that the tubes remain in good condition for longer periods of time.

The first step in the process is to prepare the aluminum coils for coating. This involves cleaning the coils to remove any dirt, oil, or other contaminants that may be present on the surface. This step is crucial, as any impurities on the surface of the aluminum can affect the adhesion of the coating and the overall quality of the finished product.

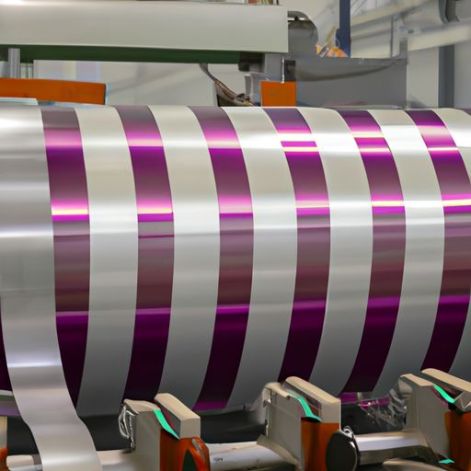

Once the coils have been cleaned, they are then coated with a layer of protective material using an extruded aluminum tube machine. This machine applies the coating evenly and consistently across the surface of the coils, ensuring that the entire surface is covered and protected. The coating material used can vary depending on the specific requirements of the project, but common options include polyester, polyurethane, and epoxy coatings.

After the coating has been applied, the aluminum coils are then formed into round tubes using a tube forming machine. This machine shapes the coils into the desired size and shape, creating seamless round tubes that are ready for use in a variety of applications. The coating on the surface of the tubes helps to protect them from damage during the forming process, ensuring that the tubes remain in good condition throughout their lifespan.

Once the round tubes have been formed, they are then inspected for quality control purposes. This involves checking the thickness and consistency of the coating, as well as ensuring that there are no defects or imperfections present on the surface of the tubes. Any tubes that do not meet the required standards are rejected and sent back for rework, ensuring that only high-quality products are delivered to customers.

Finally, the coated round tubes are packaged and prepared for shipping to customers. This involves wrapping the tubes in protective packaging to prevent damage during transit, as well as labeling them with important information such as the size, shape, and coating type. Once packaged, the tubes are ready to be sent out to customers for use in a variety of applications, from construction and manufacturing to automotive and aerospace industries.

In conclusion, coating round tubes with an extruded aluminum tube machine is a complex process that requires careful attention to detail and precision. By following the steps outlined in this guide, manufacturers can ensure that their round tubes are coated with a high-quality protective material that will help to extend their lifespan and improve their performance in a variety of applications.