Table of Contents

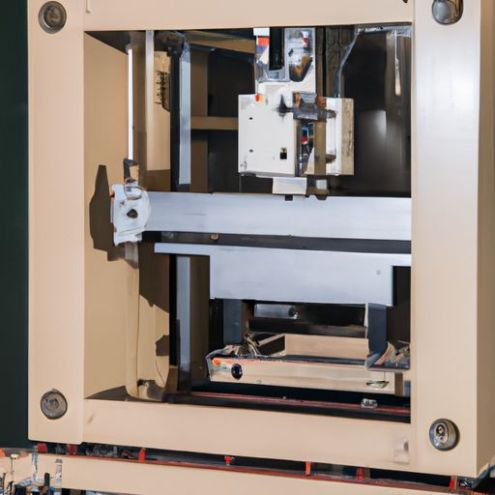

High Grade Forging Hammer Machine/Air Hammer Door Panel Embossing Machine

Door frame embossing equipment is an essential tool for creating intricate designs and patterns on metal surfaces. There are several types of machines available for this purpose, each with its own unique features and capabilities. In this article, we will focus on two popular options: the high-grade forging hammer machine/air hammer door panel embossing machine and the manual cold rolling embossing machine.

The high-grade forging hammer machine, also known as an air hammer door panel embossing machine, is a powerful and versatile tool that is commonly used in the metalworking industry. This machine uses compressed air to deliver rapid and precise blows to the metal surface, creating deep and detailed embossed patterns. The high-grade forging hammer machine is capable of producing a wide range of designs, from simple geometric shapes to intricate floral motifs.

One of the key advantages of the high-grade forging hammer machine is its speed and efficiency. This machine can quickly emboss large metal panels with minimal effort, making it ideal for high-volume production environments. Additionally, the high-grade forging hammer machine is highly customizable, allowing users to adjust the pressure, speed, and depth of the embossing process to achieve the desired results.

Another popular option for door frame embossing is the manual cold rolling embossing machine. This machine is a more traditional and hands-on approach to metal embossing, requiring the operator to manually feed the metal panel through a series of rollers to create the desired pattern. While the manual cold rolling embossing machine may not be as fast or efficient as the high-grade forging hammer machine, it offers a greater degree of control and precision over the embossing process.

The manual cold rolling embossing machine is often used for smaller-scale projects or for creating custom designs that require a more delicate touch. This machine is also well-suited for working with softer metals that may be damaged by the intense force of the high-grade forging hammer machine. Additionally, the manual cold rolling embossing machine is a more affordable option for those who are just starting out in the metalworking industry.

In conclusion, door frame embossing equipment plays a crucial role in the metalworking industry, allowing manufacturers to create unique and eye-catching designs on metal surfaces. The high-grade forging hammer machine and the manual cold rolling embossing machine are two popular options for achieving this goal, each offering its own set of advantages and capabilities. Whether you are looking for speed and efficiency or precision and control, there is a door frame embossing machine that is right for you.

Manual Cold Rolling Embossing Machine Bench

When it comes to creating intricate designs on metal surfaces, manual cold rolling Embossing Machines are a popular choice among manufacturers. These machines are versatile, easy to use, and produce high-quality results. One of the key components of a manual cold rolling embossing machine is the embossing bench. This bench provides a stable platform for the machine to operate on, ensuring precise and consistent embossing results.

The manual cold rolling embossing machine bench is typically made of high-grade materials such as steel or Aluminum to provide durability and stability during the embossing process. The bench is designed to be sturdy and rigid, allowing for smooth and accurate embossing of metal panels. It is also equipped with adjustable features such as height and angle adjustments to accommodate different sizes and shapes of metal panels.

One of the main advantages of using a manual cold rolling embossing machine bench is its versatility. The bench can be used with a variety of embossing machines, making it a cost-effective solution for manufacturers who work with different types of metal panels. Whether you are embossing door frames, panels, or other metal surfaces, the bench provides a stable and reliable platform for the embossing process.

In addition to its versatility, the manual cold rolling embossing machine bench is also easy to set up and operate. Most benches come with detailed instructions and can be assembled in a matter of minutes. Once the machine is mounted on the bench, it can be easily adjusted to the desired height and angle for optimal embossing results. This user-friendly design makes the bench an ideal choice for manufacturers of all skill Levels.

In addition to its versatility, the manual cold rolling embossing machine bench is also easy to set up and operate. Most benches come with detailed instructions and can be assembled in a matter of minutes. Once the machine is mounted on the bench, it can be easily adjusted to the desired height and angle for optimal embossing results. This user-friendly design makes the bench an ideal choice for manufacturers of all skill Levels.

Another key feature of the manual cold rolling embossing machine bench is its durability. The bench is built to withstand the rigors of daily use in a manufacturing Environment, ensuring long-lasting performance and reliability. Its sturdy construction and high-grade materials make it a valuable investment for manufacturers looking to enhance their embossing capabilities.

In conclusion, the manual cold rolling embossing machine bench is an essential component of any metal embossing operation. Its versatility, ease of use, and durability make it a valuable tool for manufacturers looking to create intricate designs on metal surfaces. Whether you are embossing door frames, panels, or other metal components, the bench provides a stable and reliable platform for achieving high-quality results. Consider investing in a manual cold rolling embossing machine bench to take your embossing capabilities to the next level.