Table of Contents

Exploring the Unique Features of DIN2391 Cold Drawn Precision Seamless Round Steel Pipe

The DIN2391 Cold Drawn Precision Seamless Round Steel Pipe is a remarkable product that has gained significant attention in the industrial sector due to its unique features. This article aims to explore these features, shedding light on why this particular type of steel pipe is highly sought after in various industries.

The DIN2391 Cold Drawn Precision Seamless Round Steel Pipe, as the name suggests, is manufactured using a cold drawing process. This process involves pulling the steel pipe through a die to reduce its diameter and increase its length. The cold drawing process not only enhances the physical dimensions of the pipe but also improves its mechanical properties. The result is a pipe with a smooth surface finish, precise dimensions, and enhanced strength.

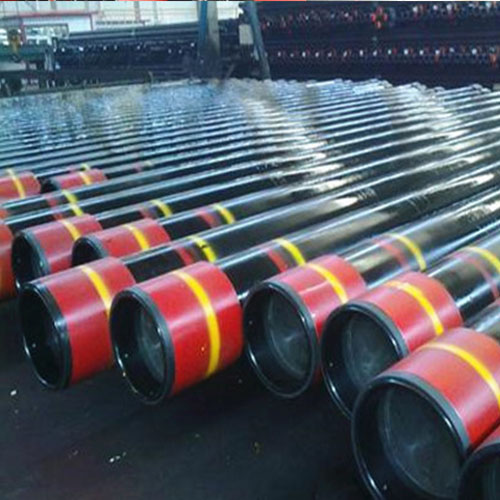

One of the most notable features of the DIN2391 Cold Drawn Precision Seamless Round Steel Pipe is its seamless nature. Unlike welded pipes, seamless pipes do not have a welded seam, making them ideal for applications that require a high-pressure capacity. The absence of a seam ensures that the pipe can withstand high pressure, high temperature, and high-stress conditions without the risk of failure at the seam. This makes the DIN2391 Cold Drawn Precision Seamless Round Steel Pipe a preferred choice for industries such as oil and gas, power generation, and chemical processing.

Another unique feature of the DIN2391 Cold Drawn Precision Seamless Round Steel Pipe is its precision. The cold drawing process allows for a high degree of accuracy in terms of dimensions. This precision is crucial in applications where exact measurements are vital. For instance, in the automotive industry, precision seamless pipes are used in the manufacture of parts such as axles, Hydraulic Cylinders, and gas Springs, where a slight deviation in dimensions could Lead to significant performance issues.

The DIN2391 Cold Drawn Precision Seamless Round Steel Pipe also boasts of superior mechanical properties. The cold drawing process refines the Grain structure of the steel, enhancing its yield strength and tensile strength. This means that despite their thin walls, these pipes can bear substantial loads without deforming. This strength, combined with their seamless nature, makes them suitable for demanding applications in construction, shipbuilding, and heavy machinery.

Furthermore, the DIN2391 Cold Drawn Precision Seamless Round Steel Pipe is known for its excellent surface finish. The cold drawing process results in a smooth and shiny surface, free from scale and other imperfections. This not only enhances the aesthetic appeal of the pipe but also provides a protective layer against corrosion. This corrosion resistance is particularly beneficial in industries such as oil and gas, where pipes are often exposed to corrosive substances.

In conclusion, the DIN2391 Cold Drawn Precision Seamless Round Steel Pipe is a versatile product with a host of unique features. Its seamless nature, precision, superior mechanical properties, and excellent surface finish make it a preferred choice for a wide range of industrial applications. As industries continue to demand high-performance materials, the popularity of the DIN2391 Cold Drawn Precision Seamless Round Steel Pipe is set to rise even further.

Understanding the Applications and Benefits of DIN2391 Cold Drawn Precision Seamless Round Steel Pipe

The DIN2391 Cold Drawn Precision Seamless Round Steel Pipe is a highly versatile and robust material that has found extensive use in a variety of industrial applications. This article aims to provide a comprehensive understanding of the applications and benefits of this unique steel pipe.

The DIN2391 Cold Drawn Precision Seamless Round Steel Pipe, as the name suggests, is manufactured using a cold drawing process. This process involves pulling the steel pipe through a die to reduce its diameter and increase its length. The cold drawing process not only refines the size and shape of the pipe but also enhances its mechanical properties, making it an ideal choice for high-pressure applications.

One of the primary applications of the DIN2391 Cold Drawn Precision Seamless Round Steel Pipe is in the automotive industry. The pipe’s high strength-to-weight ratio, combined with its excellent formability, makes it an ideal material for manufacturing various automotive parts, including axles, Drive Shafts, and suspension systems. Its resistance to high pressure and temperature also makes it suitable for use in fuel injection systems and hydraulic systems.

In addition to the automotive industry, the DIN2391 Cold Drawn Precision Seamless Round Steel Pipe is also widely used in the construction industry. Its high tensile strength and durability make it an excellent choice for structural applications, such as scaffolding and load-bearing structures. Moreover, its seamless design ensures a smooth and uniform surface, making it ideal for aesthetic applications, such as architectural design and interior decoration.

The DIN2391 Cold Drawn Precision Seamless Round Steel Pipe also finds application in the oil and gas industry. Its high resistance to corrosion and ability to withstand high pressure make it suitable for use in oil drilling and gas transportation systems. Furthermore, its seamless design ensures that there are no weak points, reducing the risk of leaks and ensuring the safe and efficient transport of oil and gas.

The benefits of the DIN2391 Cold Drawn Precision Seamless Round Steel Pipe extend beyond its wide range of applications. One of the key benefits of this pipe is its high precision. The cold drawing process ensures a high degree of dimensional accuracy, allowing for precise control over the pipe’s size and shape. This, in turn, reduces the need for further processing and ensures a high-quality end product.

Another significant benefit of the DIN2391 Cold Drawn Precision Seamless Round Steel Pipe is its high strength and durability. The cold drawing process enhances the pipe’s mechanical properties, making it highly resistant to wear and tear. This ensures a long service life, reducing the need for frequent replacement and maintenance.

In conclusion, the DIN2391 Cold Drawn Precision Seamless Round Steel Pipe is a highly versatile and durable material that offers a wide range of applications and benefits. Its high precision, strength, and durability, combined with its wide range of applications, make it an ideal choice for various industries, including automotive, construction, and oil and gas. Whether you are looking for a material for high-pressure applications, structural applications, or aesthetic applications, the DIN2391 Cold Drawn Precision Seamless Round Steel Pipe is a reliable and cost-effective choice.