Table of Contents

Stainless Steel Polishing Techniques for a Buffing Machine

Stainless steel is a popular material used in a variety of industries due to its durability, corrosion resistance, and sleek appearance. However, over time, stainless steel surfaces can become dull, scratched, or tarnished, diminishing their aesthetic appeal. To restore the shine and luster of stainless steel surfaces, many professionals and DIY enthusiasts turn to buffing machines.

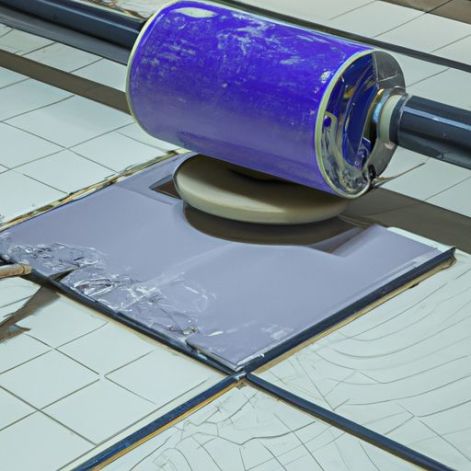

Buffing machines are powerful tools that use abrasive compounds and Polishing Pads to remove imperfections and bring out the natural shine of stainless steel. When used correctly, buffing machines can produce professional-quality results, making them an essential tool for anyone looking to maintain the appearance of stainless steel surfaces.

One of the key techniques for achieving a high-quality finish when polishing stainless steel with a buffing machine is to start with the right abrasive compound. Different compounds are designed for specific applications, so it’s important to choose the right one for the job. For polishing stainless steel, a compound with a fine abrasive grit is typically used to remove scratches and imperfections without damaging the surface.

Before applying the abrasive compound, it’s essential to clean the stainless steel surface thoroughly to remove any dirt, grease, or other contaminants that could interfere with the polishing process. Once the surface is clean, apply a small amount of the abrasive compound to the polishing Pad on the buffing machine. Start the machine at a low speed to prevent splattering, then gradually increase the speed as you work the compound into the stainless steel surface.

As you polish the stainless steel surface with the buffing machine, it’s important to use even pressure and smooth, overlapping motions to ensure a consistent finish. Pay close attention to any scratches or imperfections, as these may require additional polishing to remove completely. It’s also important to periodically clean the polishing pad and reapply the abrasive compound to maintain an effective polishing action.

In addition to using the right abrasive compound and technique, it’s also important to choose the right polishing pad for the job. Different pads are designed for specific applications, so it’s important to select the appropriate pad based on the condition of the stainless steel surface and the desired finish. For polishing stainless steel, a soft, non-abrasive pad is typically used to achieve a smooth, mirror-like finish.

When using a buffing machine to polish stainless steel, it’s important to work in small sections to ensure thorough coverage and consistent results. Take your time and pay attention to detail, as rushing the polishing process can result in an uneven finish or missed imperfections. Once you’ve completed the polishing process, be sure to clean the stainless steel surface thoroughly to remove any residue from the abrasive compound.

When using a buffing machine to polish stainless steel, it’s important to work in small sections to ensure thorough coverage and consistent results. Take your time and pay attention to detail, as rushing the polishing process can result in an uneven finish or missed imperfections. Once you’ve completed the polishing process, be sure to clean the stainless steel surface thoroughly to remove any residue from the abrasive compound.

In conclusion, buffing machines are powerful tools for polishing stainless steel surfaces and restoring their shine and luster. By using the right abrasive compound, technique, and polishing pad, you can achieve professional-quality results and maintain the appearance of stainless steel surfaces for years to come. With proper care and maintenance, stainless steel surfaces polished with a buffing machine can remain looking like new for a long time.

Tips for Achieving a High Shine on Marble with a Buffing Machine

Marble is a luxurious and elegant material that adds a touch of sophistication to any space. However, over time, marble can lose its shine and luster due to wear and tear. One of the most effective ways to restore the shine to marble surfaces is by using a buffing machine. Buffing machines are powerful tools that can help you achieve a high shine on marble with minimal effort. In this article, we will provide you with some tips on how to use a buffing machine to polish stainless steel and marble surfaces effectively.

Before you begin polishing your marble surfaces with a buffing machine, it is essential to prepare the area properly. Start by cleaning the surface with a mild detergent and warm water to remove any dirt, grime, or residue. Once the surface is clean, allow it to dry completely before proceeding with the polishing process. It is also essential to protect any surrounding surfaces or objects that could be damaged by the buffing machine’s movement.

When using a buffing machine to polish marble, it is crucial to choose the right type of polishing pad. For marble surfaces, it is recommended to use a soft, non-abrasive pad that is specifically designed for polishing delicate materials. Using a pad that is too abrasive can damage the marble surface and result in a dull finish. Additionally, make sure to apply a small amount of polishing compound to the pad before starting the buffing process. The polishing compound will help to remove scratches and imperfections from the marble surface, leaving it smooth and shiny.

When using a buffing machine to polish stainless steel surfaces, it is essential to follow similar steps. Start by cleaning the stainless steel surface with a mild detergent and warm water to remove any dirt or grime. Once the surface is clean, dry it thoroughly before proceeding with the polishing process. When polishing stainless steel, it is recommended to use a medium to fine-grit polishing pad to achieve a high shine. Apply a small amount of polishing compound to the pad before starting the buffing process to help remove any scratches or imperfections from the stainless steel surface.

When using a buffing machine to polish marble and stainless steel surfaces, it is essential to work in small sections to ensure even coverage and a consistent finish. Move the buffing machine in a back-and-forth motion, overlapping each pass slightly to avoid streaks or uneven polishing. It is also essential to maintain a consistent pressure on the buffing machine to achieve the desired shine. If you notice any areas that require additional polishing, repeat the process until the surface is smooth and shiny.

After polishing the marble and stainless steel surfaces with a buffing machine, it is essential to clean the area thoroughly to remove any polishing compound residue. Use a clean, damp Cloth to wipe Down the surface and remove any excess compound. Once the surface is clean, apply a marble or stainless steel sealer to protect the surface and maintain its shine. Regular maintenance and cleaning will help to preserve the shine of your marble and stainless steel surfaces for years to come.

In conclusion, using a buffing machine to polish marble and stainless steel surfaces can help you achieve a high shine with minimal effort. By following these tips and techniques, you can restore the luster to your marble and stainless steel surfaces and enhance the Beauty of your space. Remember to prepare the area properly, choose the right polishing pad, apply a polishing compound, work in small sections, and clean the area thoroughly after polishing. With proper care and maintenance, your marble and stainless steel surfaces will continue to shine for years to come.