Table of Contents

Benefits of Using Base Steel Stamping Housing for Conveyor Roller Spare Parts

Base steel stamping housing is a crucial component in conveyor roller spare parts, providing support and stability for the Bearings that allow the rollers to move smoothly along the conveyor system. These Housings are typically made from high-quality steel that has been stamped and formed to precise specifications, ensuring a perfect fit for the bearings and other components.

One of the key benefits of using base steel stamping housing for conveyor roller spare parts is its durability. Steel is known for its strength and resilience, making it an ideal material for applications that require heavy-duty performance. The stamping process further enhances the strength of the housing, creating a sturdy and reliable component that can withstand the rigors of continuous use in industrial settings.

In addition to its durability, base steel stamping housing offers excellent corrosion resistance, making it suitable for use in environments where exposure to moisture, Chemicals, or other corrosive substances is a concern. This corrosion resistance helps to prolong the lifespan of the housing and the components it supports, reducing the need for frequent maintenance and replacement.

Another advantage of using base steel stamping housing for conveyor roller spare parts is its versatility. These housings can be customized to accommodate different sizes and types of bearings, allowing for greater flexibility in designing and assembling conveyor systems. Whether you need a housing for a standard ball bearing or a specialized roller bearing, base steel stamping housing can be tailored to meet your specific requirements.

Furthermore, base steel stamping housing is cost-effective compared to other materials such as Aluminum or plastic. Steel is a relatively inexpensive material that offers a high level of performance and longevity, making it a cost-efficient choice for conveyor roller spare parts. The stamping process also helps to reduce waste and optimize material usage, further lowering the overall production costs.

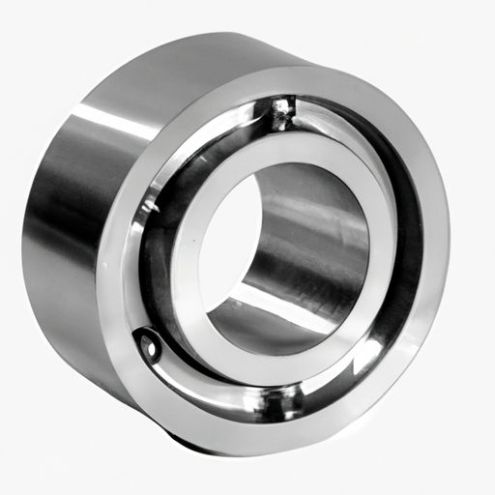

One of the most popular base steel stamping housing options on the market is the hot sale 5” tube bearing. This bearing features a chrome finish that not only enhances its appearance but also provides added protection against corrosion and wear. The 5” size is commonly used in a variety of conveyor systems, making it a versatile and practical choice for many industrial applications.

In conclusion, base steel stamping housing offers a range of benefits for conveyor roller spare parts, including durability, corrosion resistance, versatility, and cost-effectiveness. By choosing high-quality steel housings like the hot sale 5” tube bearing, you can ensure that your conveyor system operates smoothly and efficiently, minimizing downtime and maximizing productivity. Whether you are building a new conveyor system or replacing worn-out components, base steel stamping housing is a reliable and practical choice for your spare part needs.

Top Tips for Maintaining and Extending the Lifespan of Chrome Bearing Conveyor Roller Spare Parts

Base steel stamping housing ball chrome bearing conveyor roller spare parts are essential components in conveyor systems, ensuring smooth and efficient Material Handling. One of the most critical parts of these conveyor rollers is the chrome bearing, which plays a crucial role in the overall performance of the system. To ensure the longevity and optimal performance of your chrome bearing conveyor roller spare parts, it is essential to follow proper maintenance practices. In this article, we will discuss some top tips for maintaining and extending the lifespan of these crucial components.

First and foremost, regular cleaning and lubrication are key to ensuring the smooth operation of chrome bearing conveyor roller spare parts. Over time, dust, dirt, and debris can accumulate on the bearings, leading to increased friction and wear. To prevent this, it is essential to clean the bearings regularly using a mild detergent and water solution. After cleaning, be sure to apply a high-quality lubricant to the bearings to reduce friction and ensure smooth rotation.

In addition to regular cleaning and lubrication, it is also important to inspect the bearings for any signs of wear or damage. Check for any unusual noises, vibrations, or irregularities in the operation of the conveyor rollers, as these may indicate a problem with the bearings. If you notice any issues, it is crucial to address them promptly to prevent further damage and ensure the continued performance of the conveyor system.

Another essential tip for maintaining chrome bearing conveyor roller spare parts is to ensure proper alignment and installation. Misalignment of the bearings can Lead to increased wear and premature failure, so it is crucial to ensure that the bearings are installed correctly and aligned properly. Additionally, be sure to follow the manufacturer’s guidelines for installation and maintenance to ensure optimal performance and longevity of the bearings.

Furthermore, it is important to monitor the operating conditions of the conveyor system to prevent excessive wear and damage to the bearings. Keep an eye on the temperature, speed, and load capacity of the system, as these factors can impact the performance of the bearings. If you notice any issues, such as overheating or excessive vibration, it is essential to address them promptly to prevent damage to the bearings and ensure the continued operation of the conveyor system.

Lastly, regular inspection and maintenance are key to extending the lifespan of chrome bearing conveyor roller spare parts. Schedule routine inspections of the bearings to check for any signs of wear or damage, and address any issues promptly to prevent further damage. Additionally, consider implementing a preventive maintenance program to ensure that the bearings are properly maintained and serviced on a regular basis.

In conclusion, proper maintenance and care are essential for extending the lifespan of chrome bearing conveyor roller spare parts. By following these top tips, you can ensure the smooth operation and longevity of your conveyor system, reducing downtime and increasing productivity. Remember to clean and lubricate the bearings regularly, inspect them for signs of wear or damage, ensure proper alignment and installation, monitor operating conditions, and schedule routine inspections and maintenance. By taking these steps, you can maximize the performance and lifespan of your chrome bearing conveyor roller spare parts, ensuring the continued success of your material handling operations.