Table of Contents

Understanding the Role of API 9 3/8 13 3/8 Inch Oil and Gas Well Casing Oil Casing in Energy Production

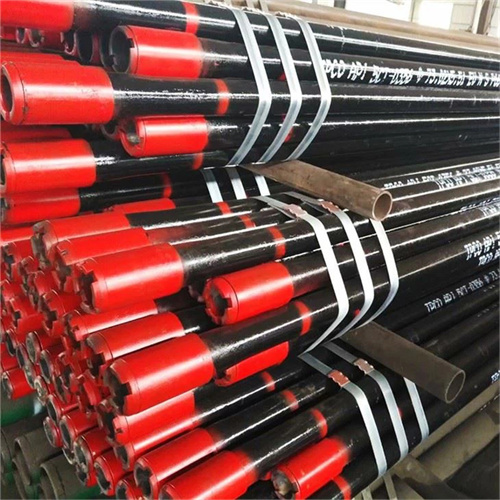

The oil and gas industry is a complex and intricate sector that relies heavily on advanced technology and sophisticated equipment. One such critical component in the energy production process is the API 9 3/8 13 3/8 inch oil and gas well casing oil casing. This specific type of casing plays a pivotal role in ensuring the efficiency and Safety of oil and gas extraction operations.

To fully appreciate the importance of the API 9 3/8 13 3/8 inch oil and gas well casing oil casing, it is essential to understand what it is and how it functions. Essentially, a casing is a large diameter pipe that is inserted into a drilled well to prevent it from collapsing. It also serves to isolate different layers of the formation to prevent the cross-flow of fluids, which could potentially Lead to contamination or loss of production.

The API 9 3/8 13 3/8 inch oil and gas well casing oil casing is a specific type of casing that adheres to the standards set by the American Petroleum Institute (API). The API is a reputable organization that sets the standards for oil and gas industry equipment to ensure safety, reliability, and efficiency. The numbers 9 3/8 and 13 3/8 refer to the casing’s diameter in inches, which is a critical factor in determining its capacity and compatibility with the well.

The role of the API 9 3/8 13 3/8 inch oil and gas well casing oil casing in energy production is multifaceted. Firstly, it provides structural integrity to the well, preventing it from collapsing under the immense pressure of the earth’s layers. This is particularly crucial in deepwater drilling operations, where the pressure from the surrounding water can be extremely high.

https://www.youtube.com/watch?v=yRqVb0LdTVkSecondly, the casing serves as a barrier to prevent the contamination of underground water sources by oil, gas, or other drilling fluids. This is a critical aspect of environmental protection in the oil and gas industry, as contamination of water sources can have devastating effects on local ecosystems and communities.

Thirdly, the casing aids in the efficient extraction of oil and gas. By isolating different layers of the formation, the casing allows for the targeted extraction of oil and gas from specific zones. This not only increases the efficiency of the extraction process but also maximizes the yield from the well.

In conclusion, the API 9 3/8 13 3/8 inch oil and gas well casing oil casing is a vital component in the energy production process. Its role in maintaining the structural integrity of the well, protecting the Environment, and enhancing extraction efficiency underscores its importance in the oil and gas industry. As such, understanding its function and significance is crucial for anyone involved in or studying this sector. The API standards that govern its design and use further emphasize the need for high-quality, reliable equipment in this industry, where safety and efficiency are paramount.

Exploring the Specifications and Applications of API 9 3/8 13 3/8 Inch Oil and Gas Well Casing Oil Casing

The oil and gas industry is a complex field that relies heavily on advanced technology and precise equipment. One such critical component is the API 9 3/8 13 3/8 inch oil and gas well casing oil casing. This specific type of casing is designed to meet the rigorous demands of the industry, providing a robust and reliable solution for a variety of applications.

The API 9 3/8 13 3/8 inch oil and gas well casing oil casing is a product that adheres to the standards set by the American Petroleum Institute (API). The API is a globally recognized body that sets the standards for equipment used in the oil and gas industry. The API 9 3/8 13 3/8 inch oil casing is designed to meet these stringent standards, ensuring that it is capable of withstanding the harsh conditions found in oil and gas wells.

The casing is made from high-quality steel, which is known for its strength and durability. The steel is treated to resist corrosion, ensuring that it can withstand the harsh Chemicals and high pressures found in oil and gas wells. The casing is also designed to be resistant to heat, making it suitable for use in high-temperature environments.

The API 9 3/8 13 3/8 inch oil and gas well casing oil casing is used in a variety of applications. One of the primary uses is to provide a stable structure for the wellbore. The casing is inserted into the wellbore and cemented into place, providing a secure and stable structure that prevents the wellbore from collapsing. This is critical for the safe and efficient extraction of oil and gas.

In addition to providing structural support, the casing also serves as a barrier to prevent the contamination of groundwater. The casing is designed to prevent any oil, gas, or other fluids from leaking out of the well and into the surrounding environment. This is a critical function, as it helps to protect the environment and ensure the safety of the local water supply.

The API 9 3/8 13 3/8 inch oil and gas well casing oil casing is also used to control pressure within the well. The casing is designed to withstand high pressures, preventing any dangerous blowouts or leaks. This is a critical safety feature, as it helps to prevent accidents and protect the safety of workers.

In conclusion, the API 9 3/8 13 3/8 inch oil and gas well casing oil casing is a critical component in the oil and gas industry. It is designed to meet the rigorous standards set by the API, ensuring that it is capable of withstanding the harsh conditions found in oil and gas wells. The casing is used in a variety of applications, providing structural support, preventing contamination, and controlling pressure within the well. Its high-quality construction and versatile functionality make it an invaluable tool in the oil and gas industry.