Table of Contents

Understanding the Key Components of API 6A Oilfield Equipment: Exploring Wellhead Casing and Tubing

API 6A oilfield equipment plays a pivotal role in the extraction and production of oil and gas. Among its key components, wellhead casing and tubing are fundamental to the integrity and efficiency of the drilling process. Understanding these components is crucial for professionals in the oil and gas industry.

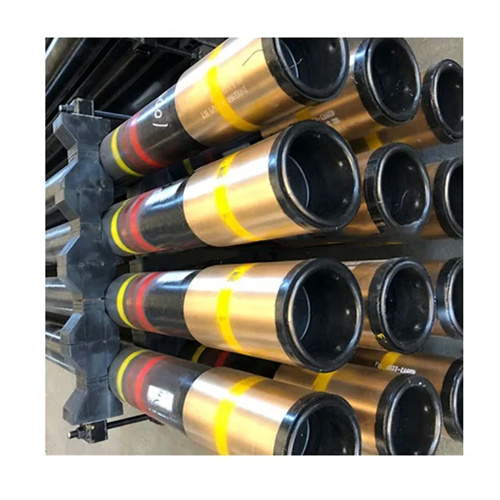

Wellhead casing serves as the primary structural support for the wellhead assembly, providing stability and sealing properties. It is typically made of high-strength steel and is designed to withstand the extreme conditions encountered during drilling and production operations. The casing is installed and cemented into the wellbore to isolate formations and prevent the escape of fluids, ensuring Safety and environmental protection.

Tubing, on the other hand, is inserted inside the casing to facilitate the flow of oil and gas from the reservoir to the surface. It is also constructed from durable materials capable of withstanding high pressures and corrosive environments. Tubing is essential for maintaining the integrity of the production string and for controlling the flow of hydrocarbons.

One of the critical components of API 6A oilfield equipment is the drilling spool casing/tubing head. This component serves as a connection point between the casing and tubing strings and provides support for various wellhead equipment, such as Valves and chokes. The drilling spool is designed to withstand the forces exerted during drilling and completion operations and to maintain a secure seal between the casing and tubing strings.

The casing/tubing head is equipped with Flanges or threaded connections to allow for the installation of additional equipment, such as blowout preventers (BOPs) and production trees. These components are essential for controlling the flow of fluids in the wellbore and for safeguarding against potential well control incidents.

In addition to providing structural support and sealing properties, API 6A wellhead casing and tubing are subject to stringent quality and performance standards. These standards are established by the American Petroleum Institute (API) to ensure the reliability and safety of oilfield equipment. Manufacturers must adhere to these standards to obtain API certification for their products, providing assurance to operators and regulators alike.

Transitional phrases such as “Furthermore,” “Moreover,” and “In addition” help to smoothly transition between different aspects of the topic, maintaining coherence and clarity for the reader. By understanding the key components of API 6A oilfield equipment, professionals can make informed decisions regarding the selection, installation, and maintenance of wellhead casing and tubing systems.

In conclusion, wellhead casing and tubing are integral components of API 6A oilfield equipment, providing structural support, sealing properties, and flow control capabilities for drilling and production operations. Understanding these components and their functions is essential for ensuring the reliability, safety, and efficiency of oil and gas extraction processes. Compliance with API standards further enhances the quality and performance of these critical components, underscoring their importance in the oil and gas industry.

A Comprehensive Guide to API 6A Drilling Spool Casing and Tubing Heads: Functions and Applications

API 6A drilling spool casing and tubing heads play a crucial role in the oil and gas industry, facilitating the extraction of hydrocarbons from deep within the earth. Designed and manufactured according to stringent standards set by the American Petroleum Institute (API), these components are essential for wellhead operations in drilling and production activities.

At the heart of any wellhead assembly, the casing and tubing heads serve as the primary interface between the surface and downhole equipment. These robust structures provide support, pressure containment, and control for various operations, ensuring the safe and efficient extraction of oil and gas resources.

One of the fundamental functions of API 6A drilling spool casing and tubing heads is to support the weight of the casing and tubing strings. Casing and tubing are critical components of a well, serving as conduits for drilling fluids, production fluids, and other materials. The casing head provides a reliable anchor point for these strings, preventing them from collapsing or shifting during drilling and production activities.

Moreover, API 6A drilling spool casing and tubing heads incorporate features for pressure containment and control. As drilling progresses deeper into the earth, the hydrostatic pressure of the surrounding formations increases. The casing and tubing heads must effectively seal the wellbore to prevent the escape of fluids and gases, maintaining well integrity and safeguarding the Environment.

In addition to pressure containment, these components facilitate the installation and operation of various downhole equipment, such as blowout preventers (BOPs) and production trees. The design of API 6A drilling spool casing and tubing heads allows for the integration of these critical safety devices, enabling operators to monitor and control well conditions effectively.

Furthermore, API 6A drilling spool casing and tubing heads play a vital role in well intervention and maintenance activities. During workover operations or routine maintenance procedures, access to the wellbore is essential. Casing and tubing heads provide convenient access points for equipment insertion, wireline operations, and other interventions, ensuring the integrity and productivity of the well.

The versatility of API 6A drilling spool casing and tubing heads extends beyond their primary functions. These components are designed to accommodate various casing and tubing sizes, allowing for flexibility in well design and completion. Whether in onshore or offshore environments, API 6A casing and tubing heads can be tailored to meet the specific requirements of each well.

Moreover, advancements in materials and manufacturing processes have enhanced the performance and reliability of API 6A drilling spool casing and tubing heads. From high-strength alloys to advanced sealing technologies, these components are engineered to withstand the harsh conditions encountered in oil and gas operations, ensuring long-term integrity and performance.

In conclusion, API 6A drilling spool casing and tubing heads are indispensable components of wellhead assemblies in the oil and gas industry. From supporting casing and tubing strings to providing pressure containment and control, these components play a vital role in drilling, production, and intervention activities. As technology advances and industry demands evolve, API 6A casing and tubing heads will continue to be at the forefront of wellhead design and innovation, enabling safe, efficient, and sustainable energy production.