Table of Contents

Benefits of Using API 5L/ASTM A106 GR.B Seamless Carbon Steel Pipe in Industrial Applications

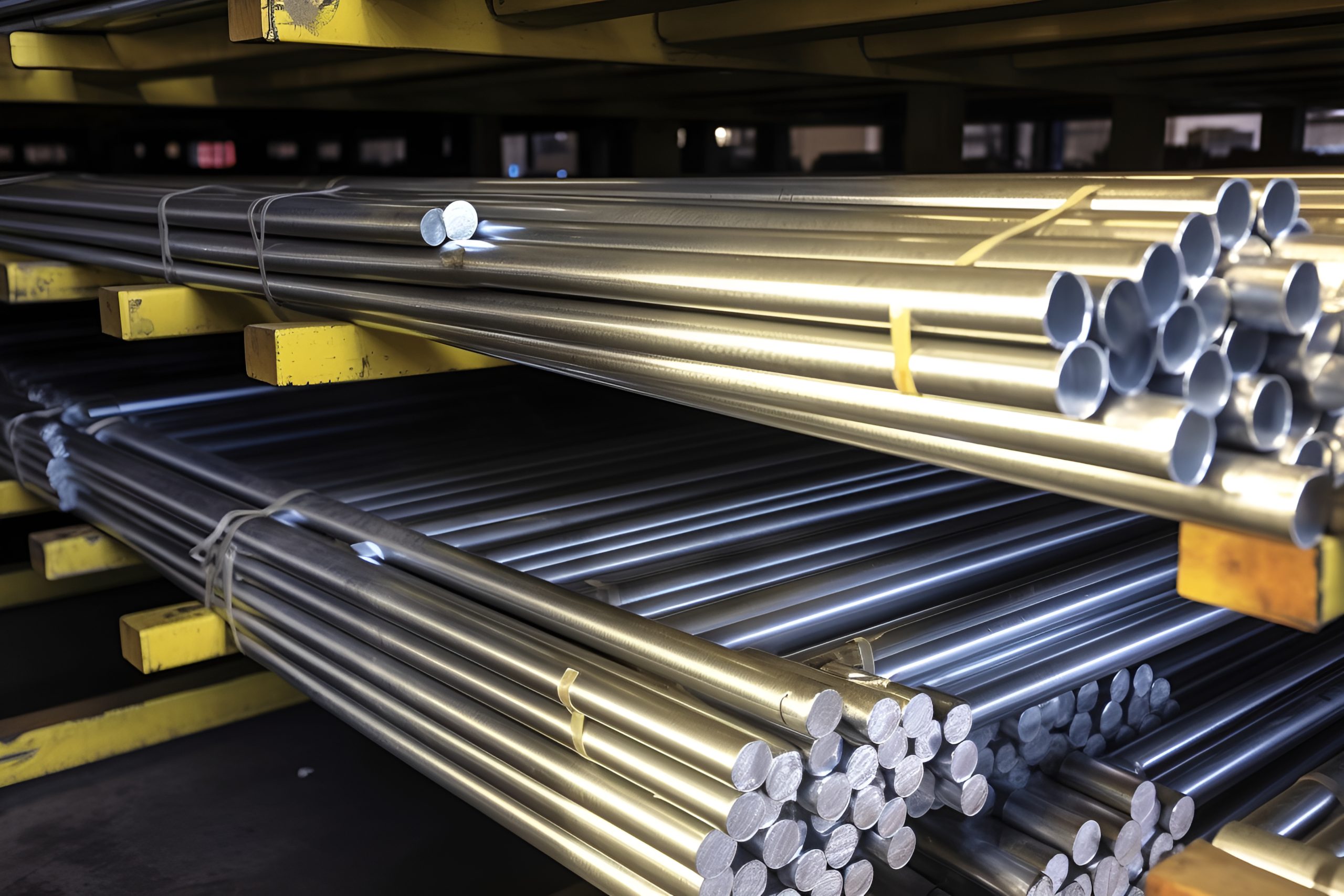

API 5L/ASTM A106 GR.B seamless carbon steel pipe is a popular choice for industrial applications due to its numerous benefits. This type of pipe is made from high-quality carbon steel, which offers excellent strength and durability. It is designed to withstand high temperatures and pressures, making it ideal for use in a wide range of industries.

One of the key benefits of using API 5L/ASTM A106 GR.B seamless carbon steel pipe is its seamless construction. Unlike welded pipes, seamless pipes do not have any seams or joints, which reduces the risk of leaks and ensures a smooth flow of fluids. This seamless design also makes the pipe stronger and more reliable, making it suitable for demanding industrial applications.

In addition to its seamless construction, API 5L/ASTM A106 GR.B seamless carbon steel pipe is also known for its high corrosion resistance. Carbon steel is naturally resistant to corrosion, making it a reliable choice for applications where exposure to harsh Chemicals or environments is a concern. This corrosion resistance helps to prolong the lifespan of the pipe and reduce maintenance costs over time.

Another benefit of using API 5L/ASTM A106 GR.B seamless carbon steel pipe is its versatility. This type of pipe is available in a wide range of sizes and thicknesses, making it suitable for a variety of industrial applications. Whether you need a small diameter pipe for a residential project or a large diameter pipe for a commercial application, API 5L/ASTM A106 GR.B seamless carbon steel pipe can meet your needs.

Furthermore, API 5L/ASTM A106 GR.B seamless carbon steel pipe is known for its high temperature and pressure resistance. This makes it an ideal choice for applications where the pipe will be exposed to extreme conditions. Whether you are Transporting hot liquids or gases, or working in a high-pressure Environment, API 5L/ASTM A106 GR.B seamless carbon steel pipe can handle the job with ease.

In addition to its physical properties, API 5L/ASTM A106 GR.B seamless carbon steel pipe is also cost-effective. Carbon steel is a relatively affordable material, making it a budget-friendly option for industrial projects. Additionally, the seamless construction of this type of pipe reduces the need for maintenance and repairs, further lowering overall costs.

Overall, API 5L/ASTM A106 GR.B seamless carbon steel pipe offers a wide range of benefits for industrial applications. From its seamless construction and high corrosion resistance to its versatility and cost-effectiveness, this type of pipe is a reliable choice for a variety of projects. Whether you are working in the oil and gas industry, chemical processing, or any other industrial sector, API 5L/ASTM A106 GR.B seamless carbon steel pipe can meet your needs and exceed your expectations.

Comparison of API 5L and ASTM A106 GR.B Standards for Seamless Carbon Steel Pipe

API 5L and ASTM A106 GR.B are two widely used standards for seamless carbon Steel Pipes in various industries. While both standards have their own unique specifications and requirements, they are often compared to determine which one is more suitable for specific applications.

API 5L is a standard set by the American Petroleum Institute (API) for the transportation of oil and gas. It covers seamless and welded steel line pipe for pipeline transportation systems in the petroleum and Natural Gas industries. On the other hand, ASTM A106 GR.B is a standard set by the American Society for Testing and Materials (ASTM) for seamless carbon steel pipe for high-temperature service.

One of the key differences between API 5L and ASTM A106 GR.B is the scope of application. API 5L is specifically designed for the transportation of oil and gas, while ASTM A106 GR.B is more commonly used for high-temperature service applications such as power plants, refineries, and Boilers. This difference in scope means that the two standards have different requirements in terms of chemical composition, mechanical properties, and testing procedures.

In terms of chemical composition, API 5L has specific requirements for the Levels of carbon, manganese, phosphorus, sulfur, and other elements in the steel. These requirements are designed to ensure the quality and integrity of the pipe for use in demanding oil and gas applications. ASTM A106 GR.B also has specific requirements for chemical composition, but these are tailored towards high-temperature service applications where the pipe will be subjected to elevated temperatures and pressures.

Mechanical properties are another important factor to consider when comparing API 5L and ASTM A106 GR.B. API 5L specifies minimum yield strength and tensile strength requirements for the steel pipe, as well as maximum hardness and elongation limits. These requirements are crucial for ensuring the pipe can withstand the stresses and pressures it will be subjected to during transportation. ASTM A106 GR.B also specifies minimum yield strength and tensile strength requirements, but these are tailored towards high-temperature service applications where the pipe will be exposed to extreme temperatures and pressures.

Testing procedures are also an important consideration when comparing API 5L and ASTM A106 GR.B. API 5L requires various tests to be conducted on the steel pipe, including hydrostatic testing, non-destructive testing, and dimensional inspection. These tests are designed to ensure the quality and integrity of the pipe for use in demanding oil and gas applications. ASTM A106 GR.B also requires various tests to be conducted, but these are tailored towards high-temperature service applications where the pipe will be subjected to extreme temperatures and pressures.

In conclusion, both API 5L and ASTM A106 GR.B are widely used standards for seamless carbon steel pipes in various industries. While they have some similarities in terms of chemical composition, mechanical properties, and testing procedures, they are designed for different applications and have different requirements to meet the specific needs of those applications. It is important to carefully consider the scope of application and requirements of each standard when selecting a seamless carbon steel pipe for a particular project.