Table of Contents

Benefits of Recycling Stationery Sheet PP Foaming Sheet into PS Conductive Sheet

In today’s world, the importance of recycling cannot be overstated. With the increasing awareness of environmental issues and the need to reduce waste, recycling has become a crucial part of our daily lives. One area where recycling can make a significant impact is in the production of stationery sheet PP foaming sheet into PS conductive sheet.

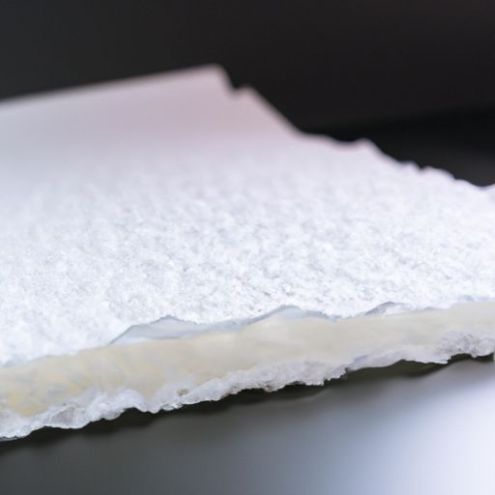

By recycling stationery sheet PP foaming sheet into PS conductive sheet, we can not only reduce the amount of waste that ends up in landfills but also conserve valuable resources. The process of recycling involves collecting used stationery sheet PP foaming sheet, cleaning and sorting it, and then processing it into a new material that can be used to create PS conductive sheet. This not only helps to reduce the demand for new raw materials but also reduces the energy and water consumption required to produce new materials from scratch.

One of the key benefits of recycling stationery sheet PP foaming sheet into PS conductive sheet is the reduction of greenhouse gas emissions. When materials are recycled, it means that fewer new materials need to be produced, which in turn reduces the amount of energy and resources required for manufacturing. This leads to a decrease in greenhouse gas emissions, helping to combat climate change and reduce our carbon footprint.

Another benefit of recycling stationery sheet PP foaming sheet into PS conductive sheet is the conservation of natural resources. By reusing materials that have already been produced, we can help to preserve valuable resources such as oil, water, and Minerals. This is particularly important in a world where resources are becoming increasingly scarce and the demand for new materials is constantly growing.

Recycling stationery sheet PP foaming sheet into PS conductive sheet also helps to create a more sustainable economy. By reusing materials and reducing waste, we can create a circular economy where resources are used more efficiently and effectively. This not only benefits the Environment but also has positive economic impacts, such as creating new jobs in the recycling industry and reducing the cost of raw materials for manufacturers.

Furthermore, recycling stationery sheet PP foaming sheet into PS conductive sheet can help to reduce pollution. When materials are disposed of in landfills, they can release harmful Chemicals and toxins into the environment, contaminating soil, water, and air. By recycling these materials instead, we can prevent pollution and protect the health of both people and the planet.

In conclusion, the benefits of recycling stationery sheet PP foaming sheet into PS conductive sheet are numerous and far-reaching. From reducing greenhouse gas emissions and conserving natural resources to creating a more sustainable economy and reducing pollution, recycling has a positive impact on both the environment and society as a whole. By making a conscious effort to recycle and support recycling initiatives, we can all play a part in creating a cleaner, healthier, and more sustainable world for future generations.

How to Choose the Right PP/PS Thermoforming Sheet for Your Needs

When it comes to choosing the right PP/PS thermoforming sheet for your needs, there are several factors to consider. Thermoforming is a process that involves heating a plastic sheet until it is pliable, then forming it into a specific shape using a mold. PP (polypropylene) and PS (polystyrene) are two common materials used in thermoforming due to their versatility and cost-effectiveness.

One important factor to consider when choosing a thermoforming sheet is the material itself. PP is known for its high heat resistance, making it ideal for applications where the sheet will be exposed to high temperatures. PS, on the other hand, is more brittle and has lower heat resistance, but is often chosen for its clarity and stiffness. Consider the specific requirements of your application when selecting between PP and PS thermoforming sheets.

One important factor to consider when choosing a thermoforming sheet is the material itself. PP is known for its high heat resistance, making it ideal for applications where the sheet will be exposed to high temperatures. PS, on the other hand, is more brittle and has lower heat resistance, but is often chosen for its clarity and stiffness. Consider the specific requirements of your application when selecting between PP and PS thermoforming sheets.

Another important consideration is the thickness of the sheet. Thicker sheets are more rigid and durable, making them suitable for applications where the formed part will be subjected to heavy use or stress. Thinner sheets, on the other hand, are more flexible and can be formed into more intricate shapes. Consider the intended use of the formed part when selecting the thickness of your thermoforming sheet.

In addition to material and thickness, it is important to consider the surface finish of the thermoforming sheet. Some applications may require a smooth, glossy finish, while others may benefit from a textured or matte finish. The surface finish of the sheet can affect the appearance and functionality of the formed part, so be sure to choose a thermoforming sheet with the appropriate finish for your needs.

When selecting a thermoforming sheet, it is also important to consider any additional properties that may be required for your application. For example, if conductivity is a concern, you may need to choose a thermoforming sheet that is treated with a conductive coating. If chemical resistance is important, you may need to select a sheet that is resistant to specific chemicals or solvents. Consider any additional properties that may be required for your application when choosing a thermoforming sheet.

Finally, it is important to consider the cost of the thermoforming sheet. PP and PS are both cost-effective materials, but the price of the sheet can vary depending on factors such as material, thickness, and surface finish. Consider your budget when selecting a thermoforming sheet, and be sure to choose a sheet that meets your requirements without exceeding your budget.

In conclusion, choosing the right PP/PS thermoforming sheet for your needs requires careful consideration of material, thickness, surface finish, additional properties, and cost. By taking these factors into account, you can select a thermoforming sheet that is well-suited to your application and will provide the desired performance and appearance.